The growing global demand for cleaner and more efficient energy sources has made Liquefied Natural Gas (LNG), among fossil fuels, a key player in the energy sector. By cooling natural gas (methane, CH4) to approximately -162 °C (-260 °F), its volume is reduced by about 600 times, creating a compact, high-energy-density fuel that is easier and more economical to transport and store.

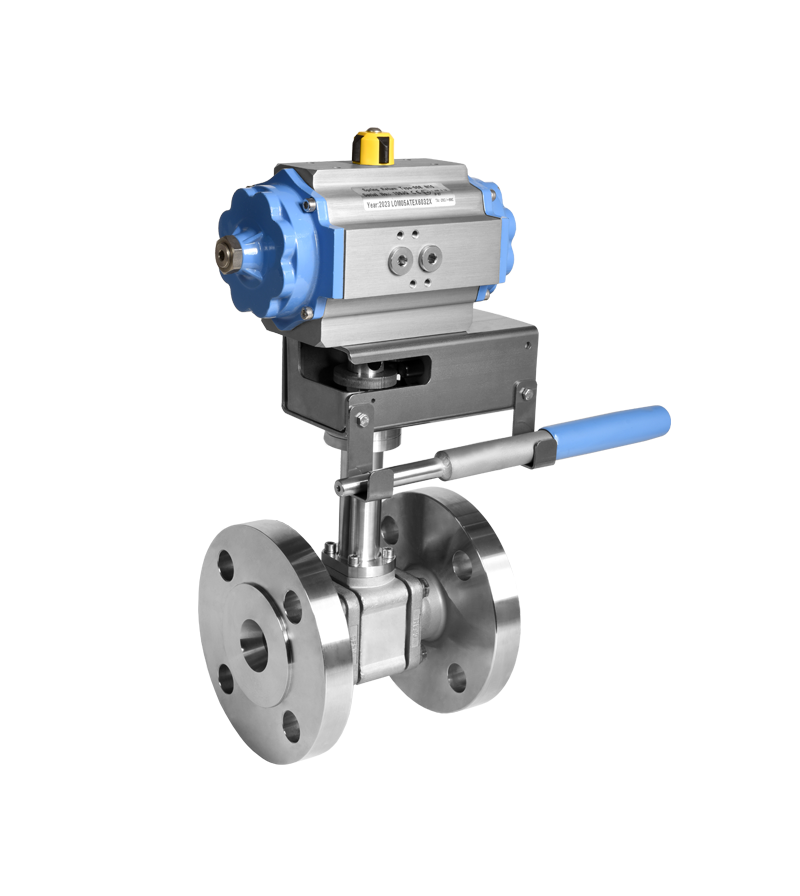

However, this cryogenic state also introduces unique technical challenges. The storage, transportation, and processing of LNG requires valves specifically designed for cryogenic service. Standard industrial valves are not suitable for such extreme conditions, as metallic materials may lose ductility, polymeric seals may fail, and thermal expansion and friction interfaces may generate unacceptable safety risks of leakage or malfunction.

Design Considerations

Cryogenic ball valves must comply with essential safety and performance requirements, particularly:

- Extended stem design, in accordance with ISO 28921-1, to prevent direct exposure of the packing system to cryogenic temperatures, by creating a separate gasified area that isolates the packing from the cryogenic conditions, improving its performance.

- Upstream relief hole, applied to prevent cavity overpressure caused by fluid expansion that could lead to rupture of the pressure-retaining parts. This is a critical design feature for liquefied gases, where the liquid-to-gas volume ratio is extremely high.

- Low-temperature compatible materials (e.g. austenitic stainless steels such as ASTM 316 or 304, bronze, or nickel alloys) to maintain mechanical integrity and prevent embrittlement. Some materials can withstand extreme temperature conditions down to -196 °C (-320 °F) without undergoing a ductile-to-fragile transition, maintaining safe levels of ductility, as demonstrated by impact test results and supported by recognized references such as ASME B31.3 – Process Piping.

- Sealing performance, validated through EN 1626, BS 6364, and ISO 28921-2 testing, ensuring tight shut-off and resistance to thermal cycling. EN 1626 is also the technical standard applied for TPED (Transportable Pressure Equipment Directive) / ADR (Agreement concerning the International Carriage of Dangerous Goods by Road) valves intended for transportable applications, where extreme design conditions – such as 2,000 cycles during type testing – are required to verify that performance capabilities are fully met.

- Fire-safe performance, validated by ISO 10497 and API 607 testing, ensuring fire safe proven design.

- Antistatic design, as required by 2014/34/EU directive, ISO 80079-36/37 and ASME B16.34, API 6D, or ISO 17292, to mitigate risks of ignition in case of abnormal operation.

- SIL-compliant design (SIL 3), in accordance with IEC 61508 and IEC 61511 standards, to ensure functional safety and mitigate risks in safety-instrumented systems during abnormal operation.

Available certifications (standards and references)

- PED 2014/68/EU – Pressure equipment directive.

- TPED / ADR (EN 1626) – Transportable pressure equipment directive / Cryogenic valves.

- ATEX 2014/34/EU and ISO 80079-36/37 – Explosive atmospheres / classified zones.

- ISO 28921-1/2 – Cryogenic service test requirements and type test.

- BS 6364 – Cryogenic Valves Specification and type test.

- DNV / BV rules – Available under request.

Applications

Typical applications include:

- LNG liquefaction plants;

- LNG storage tanks;

- LNG carriers and terminals;

- LNG regasification plants.

Each application demands strict conformity to performance standards and end-user specifications to ensure operational safety and reliability.

Vinco’s Cryogenic product range

CCF / CXF / CQF / CVT / CCT

Overfill (OPP) – Automatic over pressure shut off valve.

Fireblock (FBS) – Automatic fire block shut off valve.

Conclusion

Cryogenic ball valves are critical components in LNG infrastructure. Their design must guarantee safe and reliable performance under extreme operating conditions, fulfilling international standards and directives. The use of validated cryogenic valves reduces operational risks, ensures regulatory compliance, and provides confidence in long-term system integrity.